Another Workshop Project

Once again, my most significant journey this past week was no further than my garage workshop, but after the success of regluing the seam separation you may have seen in last week’s column, I was ready to undertake another project.

This one involved a vintage Arts and Crafts footstool which, when I found it in a Galesburg, Illinois antiques shop a few years ago, had a piece of glass atop it to serve as an end table. I’m not sure whether the footstool was a manual arts project or came from a furniture factory, but the price was right, even considering it had once been refinished.

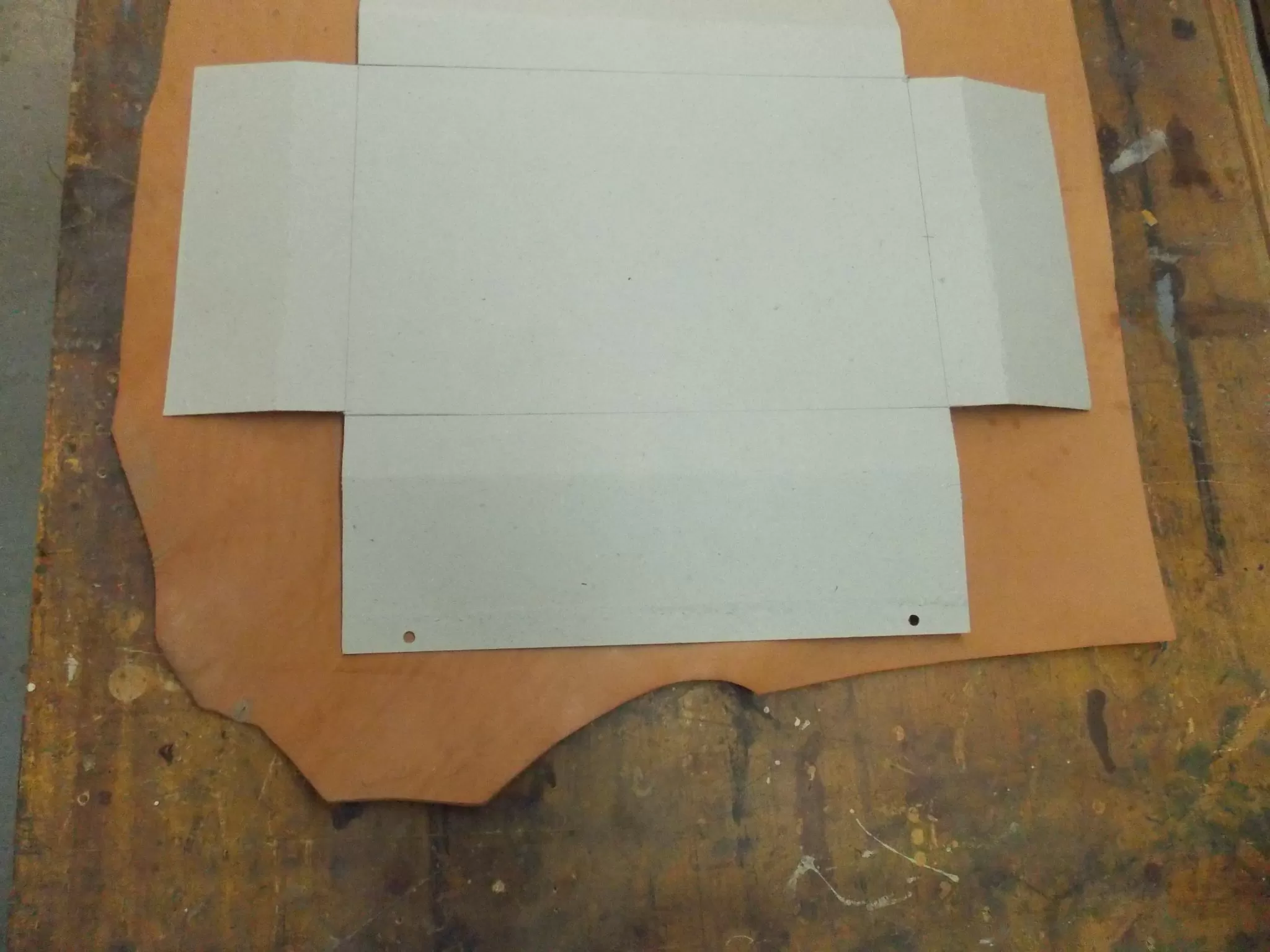

I had a large piece of thick cowhide leftover from a previous project, so I started by cutting out a paper pattern that fit around each of the four posts and arched stretchers. I then laid it on top of the leather and cut around it using a new, single-edge razor blade. I purposely left each of the four ‘tails’ a few inches longer than necessary to enable me to pull it taunt before tacking it down later.

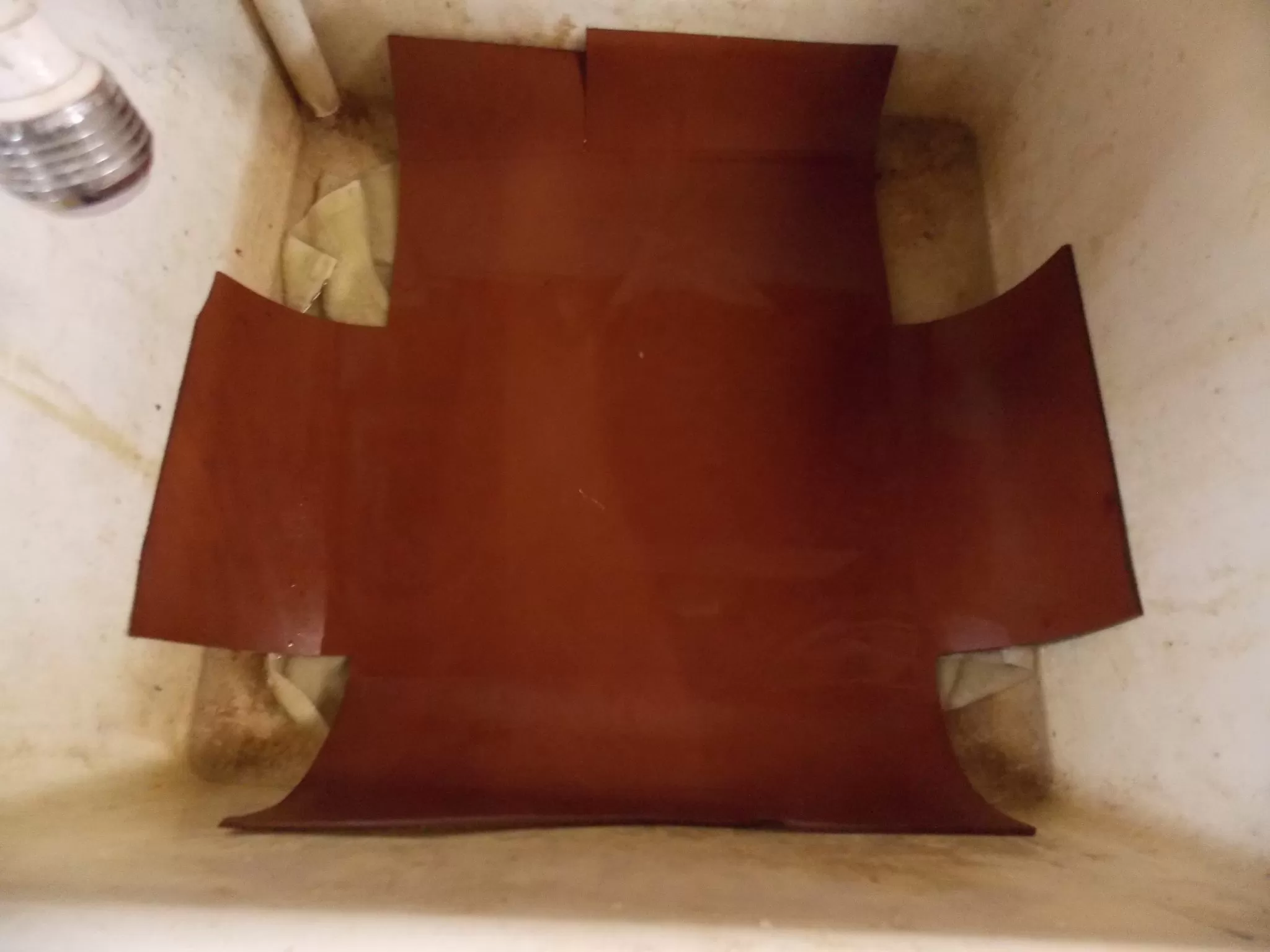

The raw leather was too stiff to wrap around the stretchers, so I placed it in the deep sink in my garage and ran water over both sides until it became pliable. (A bathtub works just as well!)

I then placed it atop the footstool and wrapped each ‘tail’ over and under the arched stretchers, pulling it tight before securing each one with a line of half-inch upholstery tacks. Afterwards I used my razor blade to trim off the excess leather — which is always easier to do while still damp.

As the leather dried, it shrank and tightened, giving me a drum-like surface. But as you can see, my leftover piece of leather had a stain across it. I wasn’t worried, because I knew from the start that I would be dyeing the natural leather to match the dark leather on an existing chair.

So, I then applied a standard ebony wood dye with a foam brush. Most of the first coat was absorbed deep into the leather, so the following day I applied a second coat to even out the color.

Afterwards, all that was needed was a coat of finish – either lacquer, shellac or paste wax – to seal the dyed leather before putting it to use. Which made me ask: if this is so easy, why did it have to wait two years for me to do it?

Until next week,

A key to happiness: Everyone should have their own desk and a workbench.

Bruce